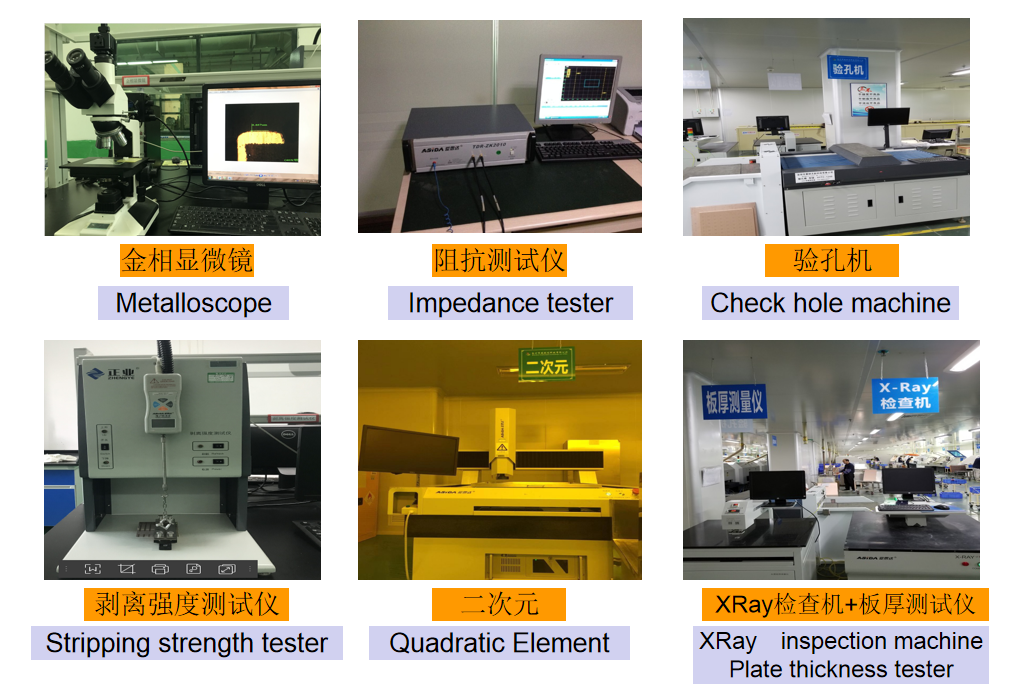

The use of advanced processing equipment to meet the needs of customers in the high-end products, has a professional quality management team, the implementation of standardized, comprehensive quality management, and has a comprehensive testing equipment, process parameters and quality of the entire process of monitoring.

PCB board production types include: flexible circuit boards, rigid circuit boards, blind buried holes, etc., involving industrial control, automotive electronics, communications, smart home and other fields.

PCB Board Needs To Provide Information:

Gerber data, PCB board process requirements (sheet thickness, copper thickness, solder resist color, silk screen color, surface treatment process) and other special requirements;

PS:The impedance board needs to provide an impedance value.

Process Parameters

|

Project |

Sample |

Quantity |

|

Layers |

22-22 Layers |

4-12 Layers |

|

Min Width/Space |

3.0 mil / 3.0 mil |

4/4mil |

|

Board Thickness |

0.4-3.2mm |

0.6-3.2mm |

|

Min hole size |

Mechanical Hole:6.0 mil |

Laser Hole:8.0 mil |

|

Laser Hole:4.0 mil |

Laser Hole:4.0 mil |

|

|

Max Aspect Ratio |

10 : 1 |

8 : 1 |

|

Impedance control tolerance |

Single-ended 50ohm or less ±5ohm, differential below 72ohm ±15%, the remaining ±10% |

Single-ended 50ohm or less ±5ohm, differential below 72ohm ±15%, the remaining ±10% |

|

Outline Tolerance |

± 0.1 mm |

± 0.13 mm |

|

Materials |

FR-4, High TG, Halogen Free, Rogers, etc. |

|

|

Surface Finished |

HASL (Lead-Free), OSP, Electroplated Gold (Only Gold Finger ), Immersion Gold |

|

|

Special processing |

Rigid-flexible combination, mixed pressure, edge metallization, buried blind hole, back drill, half hole, impedance control, etc. |

|

|

Layers |

Normal Delivery(Sample) |

Expedited Delivery (Sample) |

Expedited VS Regular Spread |

|

Single/double panel |

3-4day |

24hours |

100% |

|

4 layers |

5-6day |

3-4day |

20-60% |

|

6 layers |

7-8day |

3-5day |

20-60% |

|

8 layers |

8-9day |

4-5day |

20-60% |

|

10 layers |

9-10day |

7-8day |

20-60% |

|

PS: 1. This delivery period does not include engineering processing time and order saturation status. Please contact our staff for the specific delivery period. |

|||

Products

|

|

4Layers PCB Materials: FR4 Tg170 Layers: 4 Hole Copper Thickness: 28um Copper Thickness: 1OZ Line width/Space: 4/4mil 3/3mil PCB Thickness: 1.2mm Minimun Hole size: 0.2mm Surface Finished: ENIG |

|

|

12 Layers PCB Materials: FR4 Tg170 Layers: 12 HDI Hole Copper Thickness: 22um Copper Thickness: 1OZ Line width/Space: 2.8/2.8mil 3/3mil PCB Thickness: 0.8mm Minimun Hole size: 0.1mm Surface Finished: ENIG+OSP PCB Size: 190mm*150mm |

|

|

6Layers PCB+FPCB Materials: FR4 + FPCB Layers: 6 Copper Thickness: 1OZ Line width/Space: 4/4mil 3/3mil PCB Thickness: 1.0mm Minimun Hole size: 0.3mm Surface Finished: ENIG |

|

|

2Layers Flexible Boards Materials: Flexible Boards Layers: 2 PI Thickness: 1.6mm Tolerance: ±0.03mm Surface Finished: ENIG PCB Size: 76mm*20mm |

Lucky Dragon Technology(SZ) Co.,LTD

4F, JinXin Building, No 326, LiuTang Road, Xin an Sub-District Bao an District, Shenzhen, Guangdong, China 518100

TEL: (86) 755 23074100

Email: Sales@Ldtac.com